The Impact of Strenuous Welding Inspection on Market Criteria: Supporting Security, Dependability, and Conformity Throughout Various Sectors

The role of strenuous welding assessment is progressively recognized as an essential component in improving industry criteria, where safety and security, conformity, and integrity take priority throughout diverse fields. By making sure consistency to established standards, such as those set forth by AWS and ISO, these assessments not only alleviate threats however also cultivate a sense of accountability amongst professionals. As markets progress and face brand-new challenges, the effects of these techniques might extend beyond plain conformity. What improvements might we prepare for in welding methods as the demand for top quality and security escalates?

Significance of Welding Evaluations

Acknowledging the crucial duty of welding assessments in maintaining high quality and safety criteria, industry experts focus on these assessments to ensure architectural stability. Welding inspections offer as a vital checkpoint in the construction procedure, recognizing flaws that could endanger the sturdiness and safety of welded frameworks. By systematically assessing welds, assessors can discover concerns such as incomplete penetration, porosity, and splits, which might not be visible to the nude eye.

The value of these assessments extends beyond mere conformity; they are vital for safeguarding lives and securing investments. In critical industries such as aerospace, construction, and manufacturing, a single malfunctioning weld can bring about catastrophic failures, leading to both monetary loss and human casualties. For that reason, applying rigorous inspection protocols mitigates these risks and enhances overall project reliability.

In addition, constant welding examinations promote a society of top quality throughout companies, encouraging welders to comply with ideal techniques and preserve high requirements in their work. This dedication to high quality not only improves functional effectiveness however also strengthens the credibility of companies within their respective fields. Therefore, welding examinations are vital in advertising security, integrity, and conformity throughout different industries.

Secret Sector Standards and Laws

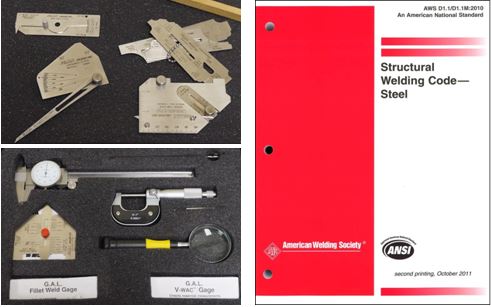

The framework of welding inspections is underpinned by a durable collection of sector criteria and laws that control methods across various industries. Trick organizations, such as the American Welding Culture (AWS) and the International Organization for Standardization (ISO), develop standards that guarantee high quality and safety in welding operations. AWS D1.1 outlines necessary requirements for welding steel frameworks, while ISO 3834 specifies top quality requirements for combination welding.

Along with these certain requirements, industry laws like the American National Standards Institute (ANSI) and Occupational Security and Health And Wellness Management (OSHA) requireds additionally boost conformity by setting safety procedures and functional best techniques. These policies are crucial in industries such as aerospace, building, and production, where welding honesty is paramount.

Moreover, sector-specific criteria, such as those from the American Culture of Mechanical Engineers (ASME) for pressure vessels, provide added layers of analysis to ensure that welds fulfill rigorous security and performance criteria. Adherence to these criteria not only facilitates governing conformity however also cultivates a society of high quality and dependability across the welding industry, inevitably protecting public well-being and improving functional performance.

Benefits of Compliance and Dependability

Continually adhering to industry requirements and regulations in welding examinations returns considerable benefits, boosting total dependability and performance. The leading benefit is the assurance of top quality in bonded joints, which straight contributes to the safety and security of frameworks and equipment. Compliance with recognized requirements minimizes the threat of failing and devastating incidents, thus securing both human life and valuable properties.

In addition, companies that focus on rigorous welding inspections foster a society of responsibility and expertise. This commitment not just boosts the credibility of the firm but additionally imparts confidence in stakeholders and customers regarding the stability of items and services. Reliable welding procedures result in decreased expenses connected with rework, fixings, and potential legal liabilities coming from poor workmanship.

Furthermore, keeping compliance with sector standards assists in smoother regulative interactions, as organizations can conveniently show adherence to necessary protocols (Welding Inspection Gilbert Arizona). This proactive approach can lead to beneficial partnerships and opportunities within the industry, along with accessibility to brand-new markets

Difficulties in Welding Examination

Navigating the complexities of welding examination provides a myriad of difficulties that can hinder conformity with market criteria. One substantial obstacle is the irregularity in inspection techniques and technologies. Different fields might use varied techniques, resulting in variances in the examination of weld high quality. The lack of standard training for examiners can result in varied analyses of inspection standards, which may endanger security and integrity.

An additional challenge hinges on the accessibility of sophisticated inspection tools - Welding Inspection Gilbert Arizona. While technologies such as ultrasonic testing and radiography can improve discovery capabilities, their execution might be restricted by cost or availability, specifically in smaller operations. This difference can cause a reliance on less efficient evaluation methods, raising the risk of unseen problems

In addition, the fast-paced nature of modern-day manufacturing typically stress inspectors to focus on speed over thoroughness, possibly ignoring crucial you can try here problems. Finally, regulative conformity can be discouraging because of the progressing nature of market requirements, leaving organizations having a hard time to stay on par with the most recent requirements. These difficulties require constant renovation in evaluation techniques to make certain the stability of welded structures across different fields.

Future Trends in Welding Practices

Emerging technologies and advancing methodologies are readied to change welding techniques in the coming years. Advancements in automation, such as robotic welding systems, are acquiring grip, improving precision and effectiveness while lessening human error. These systems will certainly not only quicken production but additionally help with consistent quality assurance, addressing several of the difficulties faced in hand-operated welding.

Furthermore, the combination of artificial knowledge (AI) and equipment learning into welding processes is positioned to change inspection and surveillance. Real-time data analytics will enable anticipating maintenance, permitting for positive treatments that lower downtime and boost safety. Moreover, enhanced reality (AR) and digital fact (VR) technologies are becoming crucial in training welders, providing immersive experiences that enhance ability growth without the dangers related to conventional approaches.

Sustainability is likewise a key fad, as sectors look for greener practices. The adoption of green materials and methods, alongside energy-efficient equipment, will likely come to be typical. As markets adjust to these changes, the emphasis will change towards better conformity with security and environmental regulations, making certain that welding practices not just satisfy existing criteria yet also lead the way for a safer and even more lasting future.

Conclusion

In verdict, extensive welding assessments substantially boost market criteria by making certain safety, dependability, and conformity across different fields. By systematically identifying issues and adhering to established guidelines, these examinations minimize threats related to architectural failures. The promo of responsibility among welders causes higher quality results, cultivating count on within areas. As industries remain to focus on functional integrity, the importance of thorough inspections will just raise, eventually benefiting businesses and society at big.

The function of rigorous welding evaluation is increasingly recognized as an important component in boosting industry standards, where dependability, security, and conformity take precedence news throughout varied industries. Hence, welding evaluations are crucial in promoting safety, reliability, and compliance throughout various markets.

Key institutions, such as the American Welding Culture (AWS) and the International Company for Standardization (ISO), establish guidelines that make sure high Discover More quality and safety and security in welding procedures. AWS D1.1 outlines vital demands for welding steel structures, while ISO 3834 defines high quality demands for fusion welding.

In conclusion, rigorous welding inspections significantly boost market requirements by making certain security, dependability, and compliance throughout various fields.